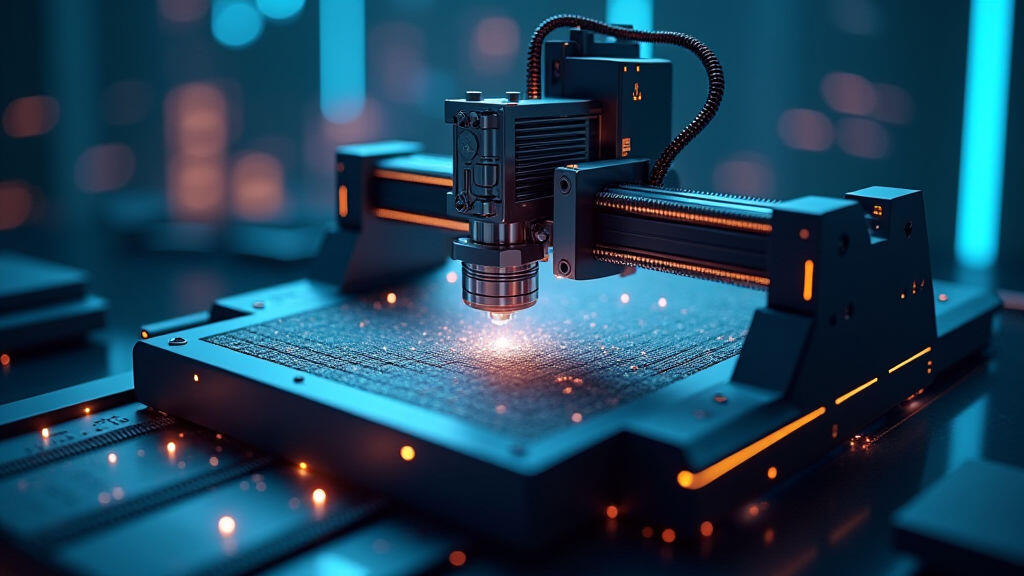

The manufacturing industry is constantly striving for greater efficiency, precision, and cost-effectiveness. In the realm of Computer Numerical Control (CNC) machine tools, advancements in drive technology play a pivotal role in achieving these goals. Among these technologies, gear motors are emerging as a crucial component, significantly boosting speed, enhancing energy efficiency, and improving the overall performance of CNC production lines. This article delves into the role of gear motors in modern CNC manufacturing, examining their benefits, key considerations for selection, and future trends.

The Importance of Drive Technology in CNC Machines

CNC machine tools are the backbone of modern manufacturing, responsible for intricate and precise fabrication processes. The accuracy and speed of these machines are directly linked to the efficiency and reliability of their drive systems. Traditional drive systems often relied on direct-drive motors, which can be powerful but frequently lack the speed and torque characteristics required for complex CNC operations. Furthermore, these systems can be less energy efficient, contributing to increased operational costs and environmental impact. This is where gear motors step in, offering a compelling alternative.

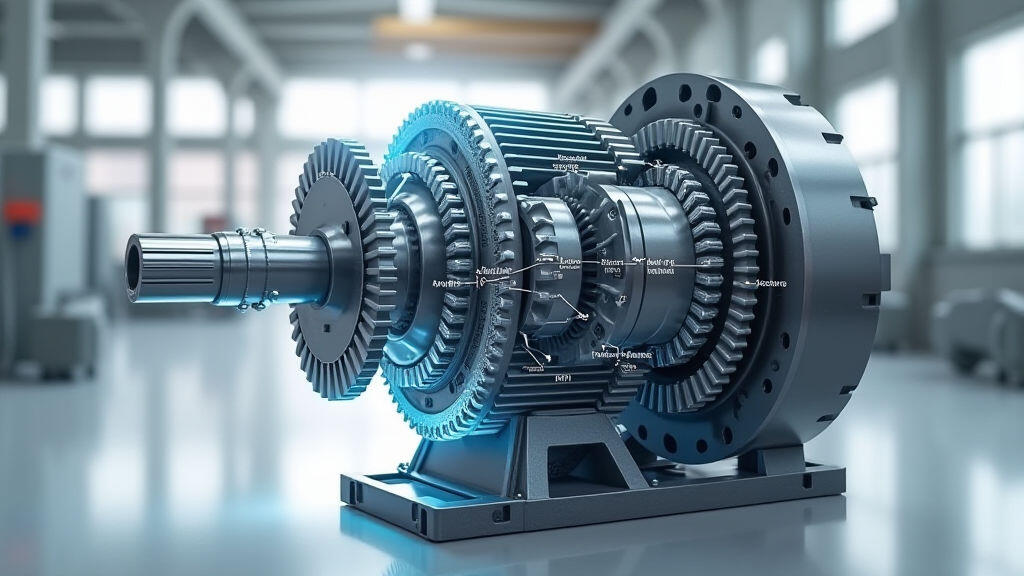

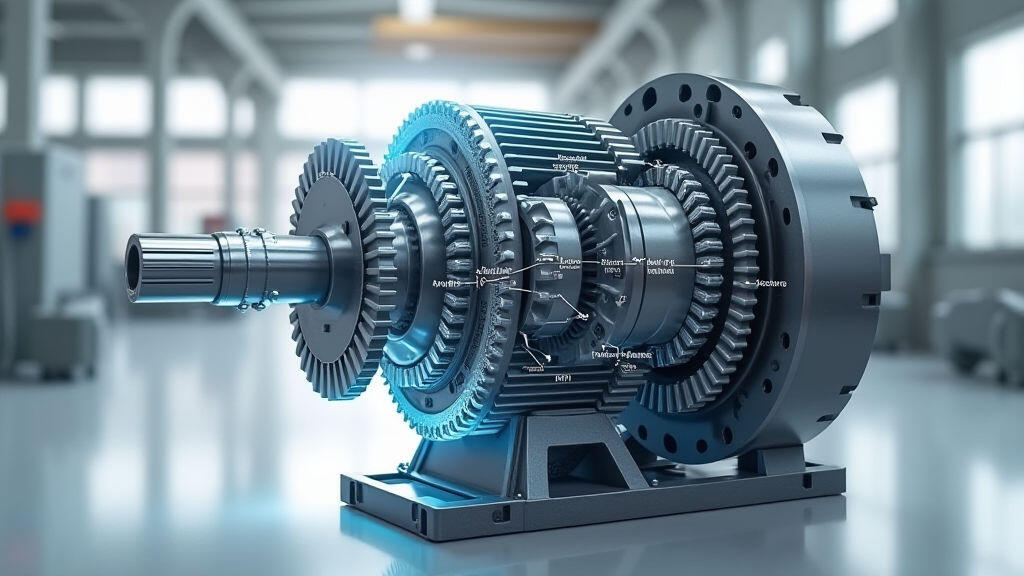

What are Gear Motors and How Do They Work?

A gear motor combines an electric motor with a gearbox. The motor provides the rotational power, while the gearbox increases the torque and reduces the rotational speed. This combination is particularly beneficial for CNC applications because it allows for high torque at lower speeds, which is ideal for tasks like milling, drilling, and turning. Different types of gear motors exist, including:

Worm Gear Motors: Known for their high reduction ratios, compact size, and self-locking capabilities. They’re commonly used in applications requiring precise positioning and holding force.

Planetary Gear Motors: Offer high efficiency, high torque density, and compact designs, making them suitable for high-speed applications.

Spur Gear Motors: Provide high efficiency and are typically used for applications where speed is critical.

The gear ratio is a critical factor in determining the performance of a gear motor. A higher gear ratio results in lower output speed and higher output torque. CNC machine tool designers carefully select the appropriate gear ratio to meet the specific requirements of their machines.

Benefits of Gear Motors in CNC Applications

The adoption of gear motors in CNC machine tools brings a multitude of benefits:

Increased Torque: Gear motors provide significantly higher torque than direct-drive motors of the same size, enabling higher cutting forces and improved machining performance. This translates to faster machining cycles and reduced tool wear.

Enhanced Speed Control: Precise speed control is essential for achieving high accuracy in CNC machining. Gear motors allow for fine-tuning of rotational speed, ensuring optimal performance for different materials and cutting operations.

Improved Energy Efficiency: By optimizing the motor’s speed and torque, gear motors can reduce energy consumption compared to traditional direct-drive systems. This not only lowers operating costs but also contributes to a smaller carbon footprint.

Compact Design: Gear motors are generally more compact than direct-drive systems with equivalent torque capabilities. This is especially important in CNC machines where space is often limited.

Reduced Vibration and Noise: Gear motors often operate with lower vibration and noise levels, contributing to a more comfortable and productive work environment.

Key Considerations for Gear Motor Selection in CNC

Choosing the right gear motor for a specific CNC application requires careful consideration of several factors:

Torque Requirements: Determine the maximum torque required for the intended machining operations, considering material, cutting speed, and tool geometry.

Speed Requirements: Specify the desired rotational speed for the application. This depends on the type of machining and the desired accuracy.

Gear Ratio: Select the appropriate gear ratio to achieve the required torque and speed characteristics.

Efficiency: Choose a gear motor with high efficiency to minimize energy consumption and operating costs.

Accuracy and Repeatability: Ensure the gear motor provides the necessary accuracy and repeatability for precise positioning and control.

Durability and Reliability: Select a gear motor that is robust and reliable, capable of withstanding the demanding conditions of CNC machine tool operation.

Environmental Factors: Consider the operating environment, including temperature, humidity, and dust levels, to ensure the gear motor is suitable for the application.

Future Trends in Gear Motor Technology for CNC

The future of gear motor technology in CNC machine tools is focused on further enhancing performance, efficiency, and intelligence. Some of the key trends include:

Integration of Smart Sensors: Integrating sensors into gear motors allows for real-time monitoring of performance parameters like torque, speed, and temperature. This data can be used for predictive maintenance and optimization of machining processes.

Advanced Control Algorithms: Developing sophisticated control algorithms can further optimize the performance of gear motors, improving energy efficiency and accuracy. This includes incorporating artificial intelligence (AI) for dynamic adjustment of motor parameters.

Miniaturization and High Power Density: Continued advancements in materials and manufacturing techniques are enabling the development of smaller, more powerful gear motors. This opens up new possibilities for compact and high-performance CNC machines.

Sustainable Materials: The industry is increasingly focusing on the use of sustainable materials in gear motor construction, reducing environmental impact.

Conclusion

Gear motors are revolutionizing CNC machine tool production lines by providing enhanced speed, improved energy efficiency, and greater precision. Their benefits extend beyond improved machine performance to encompass reduced operating costs and a smaller environmental footprint. As CNC technology continues to evolve, gear motors will play an increasingly critical role in driving innovation and achieving greater efficiency in manufacturing. The ongoing development of smart sensors, advanced control algorithms, and sustainable materials promises an even brighter future for gear motors in the CNC industry. With the increasing demand for precision manufacturing and sustainable practices, gear motors are poised for significant growth and will remain a key enabler of advanced CNC technologies in the years to come.

Leave A Reply

Your email address will not be published. Required fiels are marked